Floor Paint Vs. Marking Tape: Which Best Supports Safety in the Workplace?

Aside from maximizing efficiency and promoting a cleaner, more pleasant work environment at loading docks, shipping areas, warehouses and other commercial or industrial sites, the 5S visual management system supports another critical outcome for employers: workplace safety. Having an organized approach is vital to mitigating risks in this type of workspace, and visual cues are essential to success.

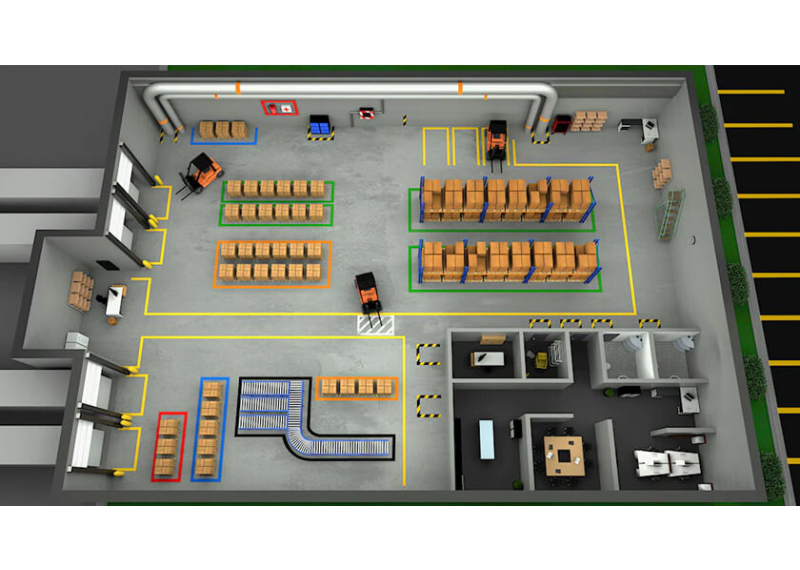

One particularly important visual cue for communicating information is floor markings, which help employees recognize boundaries, areas requiring special caution and other aspects of identification. They are instrumental in delineating lanes, signaling hazards and maintaining the structure of a workplace's visual management system.

An employer's options for implementing these markings boil down to two main choices: the more traditional floor paint and the more modern alternative of marking tape. Here, we're explaining some fundamental differences between the two and illustrating which one makes a better choice for meeting paramount workplace safety needs and supporting an effective visual management system.

Durability & Staying Power

Let's start by addressing one of the greatest concerns over floor marking products, which is their strength of adhesion and durability. Paint may have once been the go-to solution for visually marking floors in certain work environments, but the appearance and integrity of paint can erode rather quickly. In fact, painted markings may necessitate touch-ups after only a few months from application.

Fortunately, time has allowed for innovation in floor marking, and there is now the option to apply vinyl tape. High-quality tapes designed specifically for this purpose feature extreme staying power and durable adhesion, standing up to even heavy forklift traffic. With the right vinyl tape product, there's no need to worry about lifting, curling, fading or wear, so frequent reapplication is not required.

Above all, floor markings that stay put and resist erosion are vital to ensuring a safe workspace. With quality vinyl tapes, excellent abrasion resistance provides a long service life. The durable vinyl backing resists abrasion, scuffing and moisture, weathering acids and alkaline chemicals. Plus, tapes with flexible construction can stretch and conform to curved surfaces and around corners for a reliable, tight fit.

Particularly in high traffic areas, it's not uncommon for paint to scratch, forcing you to schedule regular downtime for touch-ups. But scratch-resistant tapes like 3M™ Vinyl Tape 471 are designed with a pigmented backing that maintains vivid colors, even when exposed to heavy abrasion, thereby prolonging the life of the marking.

Color & Vibrancy

Speaking of maintaining vivid colors, which is a crucial aspect of choosing your floor marking product—paint is unlikely to be your best bet for preserving color and vibrancy. Paint is certainly susceptible to fading over time, and applying a visually adept system of color coding could become a painstaking effort with this solution. Any barrier to maintaining the overall quality of your floor marking system is also a barrier to prioritizing worker safety.

Expertly constructed vinyl tape has the upper hand in the color category. Colors are locked into the vinyl so as to help maintain its vibrancy and reduce rework. Take, for example, the 3M™ Vinyl Tape 5S Color Coding Starter Pack, which is a convenient pack of color coding vinyl tapes to help implement the 5S system by providing floor marking and safety identification. The included vinyl tapes and safety stripe tapes come in a variety of bright colors that are locked into the vinyl for permanent high visibility.

Creating patterns and multi-colour markings, like hazard markings, takes extra time and effort with paint. Many vinyl tapes come preprinted with hazard markings, such as 3M™ Safety Stripe Tape 5700 and 3M™ Safety Stripe Tape 5702, helping you install critical safety features quickly and easily.

As a reference, here are some helpful color examples to be leveraged with the use of quality vinyl tapes, like those in the 3M™ collection, so as to ensure consistent, reliable visual communication and overall safety:

- Yellow - Aisles, walk-ways and traffic lanes, work cells

- Orange - Material or product inspection or temporary storage locations

- Red - Safety/first aid, defect/scrap area, red tag area

- Green - Materials and manufacturing, finished goods

- Blue - Materials and manufacturing, raw materials

- Black - Materials and manufacturing, work in progress

- Black/Yellow - Areas of potential health risks, extra caution needs to be taken

- Black/White - Areas to stay out of for operational purposes

Application & Removal Process

It's no secret that the process of painting visual lines and markings on a workspace floor requires not only a shutdown of activity on that floor, but also very specific temperature controls. If these requirements are not met, there could be real safety hazards impacting the workers in the area. What's more, paint application and removal efforts bear some risk of damaging said floors, creating another potential safety impediment.

Here again, there's a strong case for vinyl tapes that feature a more easeful and streamlined process for application and removal. 3M's assortment of vinyl tapes are constructed with pressure-sensitive rubber adhesive that sticks on contact to just about any surface for fast application with no dripping, drying or clean-up.

Employee safety is critical, and your floor marking needs can change quickly, but you also don't want to shut down production. 3M™ Floor and Safety Marking Tapes provide the flexibility to make changes quickly and efficiently without masking or waiting for paint to dry, then remove them cleanly when it's time for a change. This approach renders hazardous spills and floor damage—even in the case of fast floor marking changes—complete non-entities.

Chemical Concerns

Paint is known for emitting harmful fumes into the air, and especially in an enclosed space, this can be a substantial safety concern. Many of the paints used in floor or safety marking applications are solvent-based, which means the fumes need to be vented from open areas. These fumes can have a negative impact on the well-being of the workers in the facility.

Fortunately, opting for a vinyl tape solution for lane marking eliminates these concerns. There are no liquid chemicals involved, so there's no need to ensure adequate venting or other measures to protect against inhalation.

Flexibility & Versatility

Accommodating a safe work environment means applying floor and safety markings that meet the workspace's unique needs. And because a truly effective 5S visual management system depends on the facility's specific operations and relevant hazards, floor marking products must be capable of allowing for flexibility and versatility around such needs. Paint simply does not match the strength of vinyl tapes in this category.

Whether you need an ultra-tough tape to stand up to heavy forklift traffic or a more everyday version for walking areas and hazard marking, there's a vinyl tape product available in a variety of colors, plus applicators to make the job even easier. Vinyl tapes can be applied in straight lines, patterns or curves, and they come in multiple colors, patterns and widths. This level of flexibility and versatility breeds effective visual management for successful safety outcomes.

You're always watching to keep your floor markings matched to your current needs. 3M™ Floor and Safety Marking Tapes give you the power to customize your layout at any time, whether you're rotating machines, adding a new assembly line or streamlining your workflow.

In the end, the benefits and capabilities of quality vinyl tapes for floor and safety marking make this option a far better solution than the more traditional use of paint. And with all of these features, you're bound to glean some pretty valuable efficiency and cost savings. That's time and money that can be better spent on other areas of the business (including but not limited to your workplace safety program and implementation). So be sure to understand these considerations as you approach the task of applying floor markings that support a safer, more effective visual management system.

For detailed information about how 3M's Floor and Safety Marking Tapes can support your workplace's efforts, visit our product page or reach out to our team of experts.