5 Reasons to Get Excited About All-New Performance Abrasives

5 Reasons to Get Excited About All-New Performance Abrasives

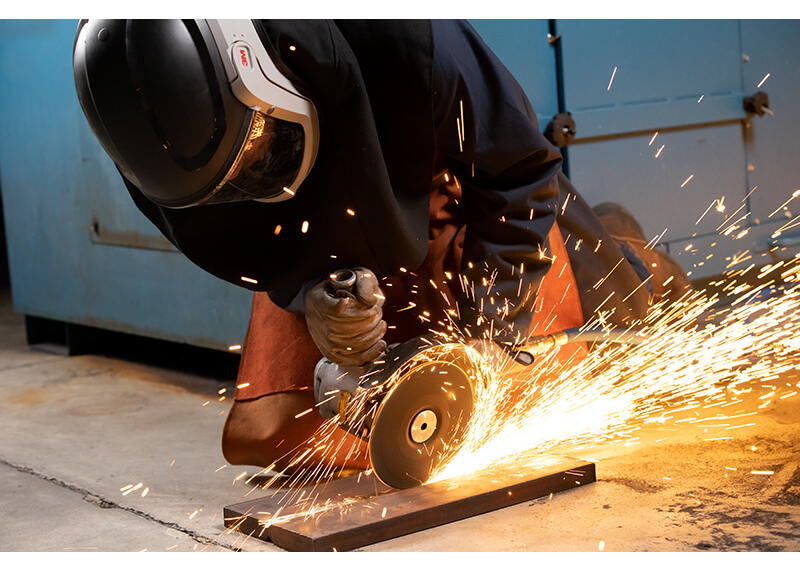

Operators in the world of heavy grinding and cutting applications understand the demand for high-performance abrasives. This field requires innovations that significantly raise the benchmark for cut rate and product life—so workers can continuously improve both efficiency and effectiveness. That's why there's been so much buzz about the introduction of a new product line designed to perform better than ever: 3M™ Cubitron™ 3 Performance Abrasives.

The key player behind this excitement is the re-engineered precision-shaped ceramic triangular grain. As these transformed abrasives begin hitting shelves and becoming available to users, there's a host of reasons why users are getting excited.

Reason #1: Experiencing Precision & Productivity Redefined

The cornerstone of advanced performance abilities lies in the re-engineering of the precision-shaped ceramic triangular grain. Traditional abrasive grains often face challenges, such as plowing through metal or generating excessive heat, thereby resulting in slower cut rates and shorter abrasive life. 3M, however, has pioneered a groundbreaking solution using its microreplication technology to form consistent sharp peaks. This allows the grain to effortlessly slice through metal, rendering a cooler, faster and longer-lasting cutting process.

And now, the re-engineered 3M precision-shaped ceramic triangular grain brings a whole new meaning to performance. This proprietary breakthrough in grain shape raises the bar and brings major advantages, like increased productivity and lower overall grinding costs.

Reason #2: Addressing Prominent Industry Challenges

Why are productivity improvements for abrasives so critical for heavy grinding and cutting applications at this time? Because the industry continues to face challenges that make performance essential to success. These include issues such as:

- Skilled Workforce Shortage: As the workforce ages, finding skilled workers becomes increasingly challenging, leading to higher labor costs and the need for de-skilling. 3M's re-engineered precision-shaped grain helps overcome these challenges with a simpler, faster, more effective solution.

- Health & Safety Compliance: Compliance with health and safety expectations, including respiratory, vibration and noise hazard exposure is a major priority in the field, given the risks and costs of noncompliance. 3M's more advanced line of performance abrasives contributes to a safer working environment.

- Process Automation: With automated processes becoming more affordable and accessible, it's necessary to integrate abrasive solutions that align with this industry shift and enhance overall efficiency.

- Inflationary Pressures: Overheads and manufacturing input costs are increasing, putting pressure on productivity. The enhanced performance of this new line, including efficiency and effectiveness, helps mitigate the impact of inflation on manufacturing costs.

- Sustainability Focus: The industry is increasingly prioritizing sustainability, with a focus on waste reduction and environmental preservation. 3M's abrasive technology contributes to this goal by improving overall efficiency and reducing the need for frequent replacements.

Reason #3: Taking Efficiency to the Next Level

To meet the industry challenges listed above, the re-engineered 3M precision-shaped ceramic triangular grain is a game-changer. Its proprietary breakthroughs in grain shape not only address the issues of conventional abrasive grains, but also lead to increased productivity and lower overall grinding costs. By cutting cooler and faster, the abrasive lasts longer, reducing the frequency of replacements and downtime.

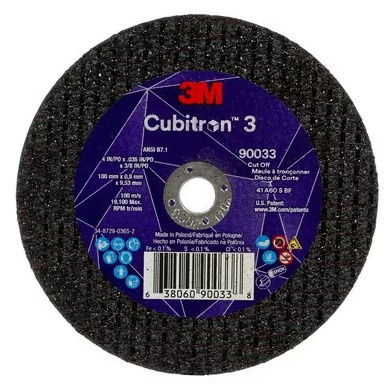

Reason #4: New Cubitron™ 3 Portable Bonded Wheels

As part of this transformative journey, 3M™ Cubitron™ II Portable Bonded Wheels are discontinuing and being replaced by the upgraded 3M™ Cubitron™ 3 Portable Bonded Wheels. These new wheels feature the re-engineered 3M precision-shaped grain, incorporating proprietary breakthroughs in molecular bonding technology. The result is a product that not only improves performance, but also enhances customers' productivity, aligning with the evolving needs of the industry.

Customers will benefit from a wider product choice, better performance and optimized sustainability with no change in list price. Check out this article for more detailed information on the specific products in the newly designed line, including:

- 3M™ Cubitron™ 3 Depressed Center Grinding Wheels

- 3M™ Cubitron™ 3 Cut-Off Wheels

- 3M™ Cubitron™ 3 Cut and Grind Wheels

Reason #5: The Best Getting Even Better

There's no more valid reason to get excited about 3M's all-new line of performance abrasives than the fact that they have taken an already top-notch technology and made it even better. The transition presents a paradigm shift in the field of heavy grinding and cutting applications. This re-engineered precision-shaped ceramic triangular grain, with its innovative grain shape and molecular bonding technology, both addresses current industry challenges AND anticipates and adapts to emerging trends.

Such an evolution marks a significant leap forward in the pursuit of efficiency, productivity and sustainability in abrasive manufacturing. As industries evolve, so too do the tools that drive progress, and these performance abrasives are leading the way into a future of enhanced precision and productivity.

Look for these exciting, new offerings to become available here for purchase soon. For questions, reach out to our team of experts.