Why Surface Energy Is The Key To Getting A Good Bond

A Guide To The Best

Adhesives, Based On Surface Energy

Part 2 of a two-part blog on surface energy and its effects on adhesives

For manufacturers that considering a liquid adhesive to bond two materials together, the most important thing to remember is if it doesn't wet-out, it won't bond. You must consider the surface energy of the substrate when determining whether or not the adhesive will bond.

In addition to liquids, pressure sensitive adhesives - also known as tape - need a good wet-out for a strong bond. Unlike liquids that cure on the surface, pressure sensitive adhesives flow into the microstructure of the surface and form bonds through intermolecular forces.

Higher surface energy substrates tend to pull PSAs better and hold on to them better than lower surface energy substrates, which tend to prevent this close contact.To activate a pressure sensitive adhesive, you need to start the wet-out process by applying pressure. After getting it started by pressing down on it, the wet-out process will continue on its own.

Selecting The Right Adhesive

To get the best results from your adhesive bonds, you need to know the surface energy of the materials you're using. There are a few exceptions - think chemical-based reasons like covalent bonding and diffusion.

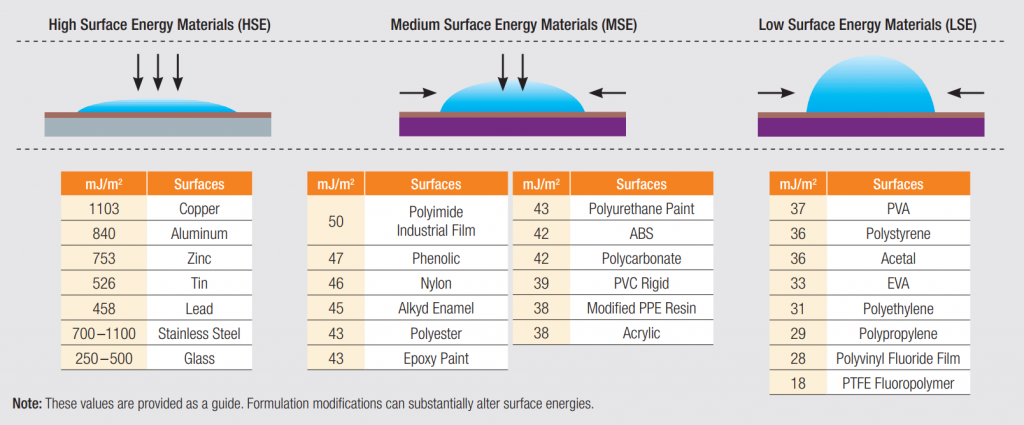

Here's a graph that helps break down materials into three categories - high, medium and low surface energy materials - and offers some good examples of each one:

So which adhesive works best with which materials?

- Most adhesives will bond most High Surface Energy materials after cleaning the substrate.

- Rubber adhesives/pressure sensitive adhesives will bond most Medium Surface Energy materials.

- Acrylics will bond to many Medium Surface Energy substrates but using a primer will help improve adhesion.

- Epoxy adhesives aren't a good option for most Medium Surface Energy substrates.

- Low Surface Energy substrates are very difficult to bond. They need specialty adhesives and/or surface treatments and primers to get a strong bond. 3M™ 300LSE Low Surface Energy Acrylic Tapes and 3M™ Scotch-Weld™ Structural Plastic Adhesive DP8010 Blue are two examples of adhesives designed to bond to some Low Surface Energy materials without a primer.

Other Factors Affecting Bonding

While surface energy plays a big role in the adhesion process, it's not the only factor you need to consider. Things like surface roughness, contamination, surface treatments, diffusion, temperature, CTE, active chemistry and more also affect how well bonding occurs.

Use this information to select a few products for testing, but remember that nothing will be more important than actually doing real-world tests to see how each adhesive performs for your specific product.

Have more questions? Post a question to 3M's assembly forum or to learn more about the science behind surface energy, read our previous blog.

See Why We're The Top Supplier For Industrial, Marine and Safety

30-Second Summary:

- ✔ Selecting the right adhesive for your product starts by determining the surface energy of your materials.

- ✔ Surface energy falls into three categories - high, medium and low.

- ✔ Different materials work better for some surface energies than others. Here's a quick overview:

- Most adhesives will bond most High Surface Energy materials after cleaning the substrate.

- Rubber adhesives/pressure sensitive adhesives will bond most Medium Surface Energy materials.

- Acrylics will bond to many Medium Surface Energy substrates but using a primer will help improve adhesion.

- Epoxy adhesives aren't a good option for most Medium Surface Energy substrates.

- Low Surface Energy substrates are very difficult to bond. They need specialty adhesives and/or surface treatments and primers to get a strong bond.

- ✔ Things like surface roughness, contamination, surface treatments, diffusion, temperature, CTE, active chemistry and more also affect how well bonding occurs.

- ✔ While understanding surface energy is important, the best way to ensure you have the right adhesive is to run real-world tests with several different adhesives.