Let Very High Bonding (VHB) Tape Bring Your Projects Together

Use VHB Bonding Tape To Seal Together

Two Different Substrates

Joining similar substrates together is straightforward - you can weld metal or glue wood. But the manufacturing process gets much more complicated when you need to join together two different substrates, like thin sheet metal to framing, wood to metal or Plexiglass to pretty much anything.

Further complicating the process are questions like how you hold a product together while the adhesive sets or how you can keep out the elements along the sealed edge.

3M has the answer to this manufacturing dilemma - VHB tape. This bonding tape is designed to bring together a wide variety of substrates, letting you immediately put materials together while also sealing out the elements. This product ensures you can get your products out the door, in a cost-effective and reliable manner.

So how does bonding tape work?

Very High Bond Tape

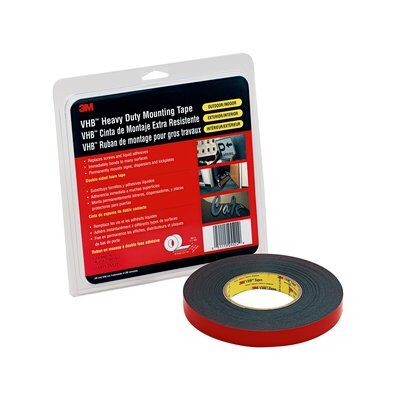

3M's VHB, which stands for “Very High Bond,” is a line of double-sided tapes that offer incredible holding power.

To break it down, VHB tapes are basically firm acrylic pressure-sensitive adhesives developed to slowly migrate into surface profiles, creating a very secure grip. It's almost like a liquid flowing over a surface, except in this case the liquid is a flexible solid.

One of its key qualities is its flexibility, which allows it to stretch under load and then return to its original shape. This “viscoelasticity” is at the core of VHB's key functionality. It's most useful in situations where a rigid bond wouldn't work well - such as loaded trailers traveling along the highway, signs being hit with high winds during a storm, cameras being dropped, commuter busses hitting potholes and other scenarios that products need to withstand without failing.

Another key strength of VHB is the continuous bond it creates as it spreads the load across the entire length of the bonded area. This means that even relatively weak materials like aluminum sheets can be held firmly in place without screws or rivets pulling through or eroding their pilot holes. This also prevents the need for messy adhesives, and allows you to quickly and neatly assemble the product.

Since these tapes are 100% closed cell, the finished bond area is extremely weather tight and the elastic nature absorbs vibrations, reducing noise. VHB tapes are easily die cut to speed assembly of complicated parts, providing exact bonding without the need for messy, liquid adhesives.

How Does Traditional Joining Compare To Tape Bonding?

To better understand where tape bonding might work well in your manufacturing operations, let's see how it compares to traditional joining methods.

Let's start with rivets and screws. A simple joining method, all you need to do is drill a hole through your materials and drive in a screw or pop in and buck a rivet and it's finished. One exception is when you're working with large pieces. This requires you to fixture parts and repeat the process repeatedly.

Rivets and screws leave you with a snug, secure join that is pretty much guaranteed to stay in place unless it's going to be subjected to the noise and vibration over the road or other vibration-heavy environment. These stressors wear over time, causing the holes to become larger and the movement along the point of contact to increase.

Ultimately, this leads to a sloppy or damaged product. If the product has gotten wet or dusty, it can corrode or damage the parts, leading to failure or diminished performance.

Trading VHB For Rivets, Screws

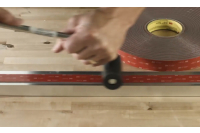

So what happens if you substitute VHB tape for the rivets and screws? You get an entirely different outcome. You just need to do a little surface prep, then roll the tape onto one side of the assembly, remove the liner, and carefully put them together. Just roll over the seam with a roller and you're finished.

The load bearing is distributed across the entire length of connection, reducing stress points and creating a stiffer assembly. Once the product is in motion, all vibrations are absorbed into the panels instead of being transmitted through the joints.

To test its weather-resistance, just spray it with water. Your seams are weather-tight and no water or dust is getting in! VHB gives you a quality product that lasts years longer than with traditional methods and you can show off the quality you added in the assembly process.

VHB Vs. Adhesives

Now, let's look at how VHB tapes compare to adhesives. You can see the most differences in the assembly stage. As I mentioned in the previous comparison, tape bonding is fast, precise and clean with no fixturing or VOC issues.

This isn't the case with adhesive bonding. Your product will need similar surface prep - usually a little abrasive scuff and solvent wiping - but when you put the adhesive down, your parts will need to sit until the adhesive reaches ‘“green strength,” which varies with different cure times and methods.

“Green strength” means that your product has cured enough that you can handle it gently. Silicone, urethane, and silanes are moisture cure and while some are called “fast set,” none give you the ability to handle it immediately like VHB tapes do.

Two-part adhesives like epoxy or methacrylate cure cycles can be chosen, but you need to work quickly to avoid misaligned parts. The other issues to consider with these adhesives are the cleanup of squeezed-out adhesive and the variable thickness in the finished product.

This leads me to another benefit of VHB - the appearance of the final product. While you may like the look of exposed rivets or screw heads, it doesn't work for all products. Sometimes the clean look of VHB tape joints is what you need. You'll get a more finished look, which also allows you to apply decals, skins and painted graphics, which really pop. You also avoid bumps or rough edges, your paints don't crack around the screw and rivet heads or glue joints, and the whole assembly has a more solid feeling due to the dampening effect of the tape. Plus, you never have to worry about dimpling.

Selecting The Right VHB Tape

If you decide to use VHB in your product manufacturing, make sure you choose the right VHB tape for your specific needs. Some offer higher tensile, shear or peel adhesion. Others have higher resistance to solvents, plasticizer migration or moisture. A few have U.L. recognition, while others have film vs. paper liners.

You can also find VHB tape that ranges from very firm to very conformable, depending on what your product requires. For low-temperature products, there are a few VHB tapes that work in that setting.

Overall, VHB tapes are great for bonding a range of substrates, including metal, sealed wood, glass and Plexiglass, composites, plastics and painted surfaces. Special use cases, like certain low surface energy plastics (polyethylene and polypropylene), require a surface primer like our #94 primer, but the final bond strength VHB delivers is impressive.

Have more questions?

Check out our bonding tape page to learn more about how to use it in your manufacturing operations.

See Why We're The Top Supplier For Industrial, Marine and Safety

30-Second Summary:

- ✔ VHB tapes offer an easier and higher performing way to bond two different substrates together, while also sealing out the elements.

- ✔ VHB offers an alternative to traditional joining methods like screws and rivets.

- ✔ Unlike rivets and screws, VHB distributes the load bearing across the entire length of connection, reducing stress points and creating a stiffer assembly and absorbing all vibrations.

- ✔ VHB comes in a wide variety of options, so you can tailor it to your specific manufacturing needs. Some offer higher tensile, shear or peel adhesion. Others have higher resistance to solvents, plasticizer migration or moisture. A few have U.L. recognition, while others have film vs. paper liners.