How to Decode the Roloc™ Disc Color System

How to Decode the Roloc™ Disc Color System

The 3M™ Roloc™ color-coded disc system has revolutionized the world of abrasive discs, providing a quick and intuitive way to identify grit levels for different applications. A staple tool for professionals in industries ranging from automotive to metalworking, the system employs a spectrum of colors, each denoting a specific grit size—making it easy for users to select the appropriate disc for their particular task. Understanding the nuances of these colors and their corresponding grit levels is crucial for achieving optimal results in any application.

To help decode this system and bring some helpful information to light, we're breaking down the details of the Roloc™ color coding system, highlighting what each hue signifies, and offering practical guidance on how to choose the right type of disc for your specific needs.

What is Roloc™?

3M™ Roloc™ Abrasive Discs are discs that quickly attach onto a Roloc™ disc pad so that you can conveniently and rapidly change discs as needed. This system provides a secure attachment for a variety of applications (even heavy-duty ones), including:

- Remote applications

- Retaining extra control

- Localized, refining, finishing

- Corner or curved surfaces

- Intricate, difficult-to-reach areas

- Removing weld splatter on small areas

With the easy-to-use 3M™ Roloc™ Quick Release System, operators can select the 3M product most suited to the application. Changing products or grades is as simple as a quick twist-off, twist-on motion and can be managed in three easy steps:

- Fit the 3M™ Roloc™ Back-Up Pad or 3M™ Roloc™+ Plastic Holder on your die grinder or disc sander.

- Twist-on your Roloc™ or Roloc™+ abrasive disc.

- Twist it back off when you need to change discs.

3M™ Roloc™ Abrasive Discs are designed to be used on the face of the disc, while 3M™ Roloc™+ Abrasives are designed for use on workpiece edges and have a longer shaft for extra strength. Both series are available for a wide range of applications from finishing and cleaning to grinding and deburring.

Understanding the Color Coding System

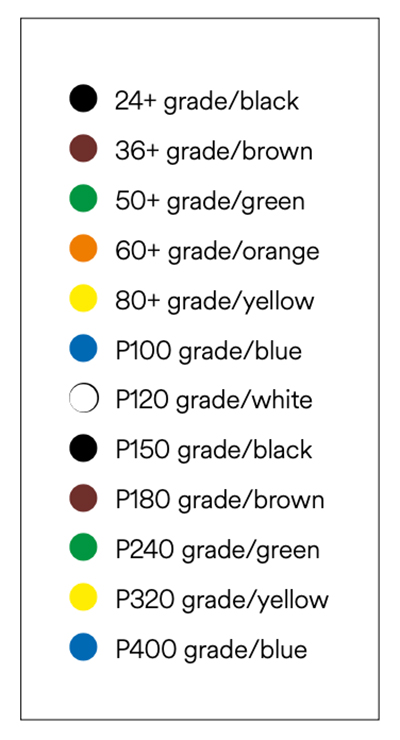

Roloc™ discs are also color-coded to identify their grade, making it easy to select the grade required for different applications. Each color correlates to a specific grit strength of abrasive.

While there are some specific exceptions to the color coding system to account for various product types and special circumstances, the general rule for Roloc™ disc colors is as follows:

You can identify the disc's grit by viewing the color of the button in the center of the disc.

Choosing Your Disc Type

In addition to grit specification, it's important to ensure you're choosing the right discs with the attachment design made for your system. Here's a closer look at some of the available disc offerings for various applications.

3M™ Roloc™ Disc 777F

- A blend of ceramic and aluminum oxide mineral self-sharpens and offers improved durability and cut-rate over aluminum oxide

- Polyester backing is extremely tough to support medium-pressure applications while maintaining consistent performance in both wet and dry applications

- Grinding aid reduces grinding temperatures for processes involving heat-sensitive alloys such as stainless steel, nickel alloys, and titanium

- Heat-resistant resin coating bonds abrasive to backing for durability under pressure, heat, and water

- Available for use with the following Roloc™ attachment systems: TSM, TR, TP and TS

3M™ Roloc™ Disc 361F

- Durable aluminum oxide abrasive grains cut fast and perform well on many surfaces

- Tough YF-weight, polyester backing supports medium-pressure applications and provides consistent performance

- Heat-resistant resin coating bonds abrasive to backing for durability under pressure, heat, and water

- Disc can be used in wet or dry applications

- Available for use with the following Roloc™ attachment systems: TSM, TR, TP and TS

3M™ Roloc™ Fibre Disc 787C

- Rapidly cuts hard-to-grind metals like stainless steel and high-nickel alloys

- Premium mineral excels at heavyweight applications such as weld grinding, beveling and edge chamfering

- 3M Precision Shaped Grain yields higher cut rates and cooler cut while completing more parts per disc than conventional fibre discs

- Grinding aid minimizes grinding temperatures for heat-sensitive alloys

- Long-lasting disc helps reduce cost

- Stiff fiber backing and strong resin bond provide durability and tear-resistance

- Available in 2-4" diameters for use with the following Roloc™ attachment systems: TSM and TR.

Scotch-Brite™ Roloc™ Bristle Disc

- Molded, abrasive filled bristles strip, deburr, blend, finish, polish, clean, and remove coatings more effectively than wire brushes

- Proprietary 3M™ Ceramic Abrasive Grain blend provides high degree of finish quality throughout the life of the disc

- Bristle spacing is ideal for coating removal and other high-loading substances

- Flexible bristles conform to contours to produce consistent finishes, even on complex parts

Scotch-Brite™ Radial Bristle Disc

- Molded, abrasive-filled bristles strip, deburr, blend, finish, polish, clean and remove coatings more effectively, with less pressure than wire brushes

- Proprietary 3M™ Ceramic Abrasive Grain provides aggressive cutting and consistent finish quality throughout the life of the disc

- Flexible bristles require less pressure than wire brushes and conform to contours, even on complex parts

- Bristle spacing is ideal for coating removal and other high-loading substances

- Contains no wire filaments for improved safety

For more detailed information about how Roloc™ discs can support your specific application needs, visit our product pages or reach out to our team of experts.